How to install Engineered Click Flooring?

How to install Engineered Click Flooring?

Here is our 5G Engineered Oak Fitting Instructions:

1. Introduction:

Congratulations with

your new 5G LOC European Engineered Flooring. This product requires a 48 hour

period of acclimatization; stored flat and to remain in the sealed packaging

until the date of installation. It is your responsibility to ensure that your

site conditions are within the stated requirements. This floor should only be

used in dry rooms with normal temperature and air humidity. It should also be

installed as a floating floor on a level and solid wooden or concrete subfloor.

Any old carpets or PVC should be removed. Please ensure that any concrete

subfloor is dry enough before you begin the installation. Use a moisture meter

to check that the moisture content of the subfloor is less than 2%. When this

product is installed with an Underfloor Heating system, be aware that the

moisture conditions are much stricter for this type of installation - 1.8% for

Concrete and 0.5% for Anhydrite. We always advise that you contact your

Underfloor Heating supplier/installer for more details before installation.

2.

Product Grading:

To establish product

consistency; a grading and manufacturing tolerance of 5% has been set to allow

for the de-selection of material if deemed by the customer/installer to be

unsuitable for the installation. A 5% cutting or waste allowance must,

therefore, be taken into consideration and added onto the net square meterage

required for the site. We recommend keeping any spare boards for any subsequent

repairs in years to come. Due to the

quality of our 5G LOC system full plank replacement is possible to do.

Note: Keep a record of

all your moisture readings for later reference and warranty enquiries. We

strongly recommend you keep a record of your moisture and humidity readings

before installation. These measurements will be required by the manufacturer or

supplier if there are any future problems or warranty claims.

3.

General Installation Information:

3A) Preparation -

Tools needed: Distance wedges, hand block, installation support wedge, hand saw

or electric jig-saw, pencil, measuring tape, drill, chisel + hammer, dustpan

and brush.

3B) Check your

Subfloor: Carpets must be removed. You can install our engineered flooring on

all kinds of subfloors if they are dry, flat, fixed and clean, for example on

old wood floors (install at right angles to existing floor), cement/concrete

floors or ceramic tiles. If the subfloor

is of other material, please contact Ukflooringcompany who will be happy to

advise you. The sub floor must be dry: Always measure the moisture content of

cement screed / concrete / anhydrite with professional test instruments and

record readings. Cement screed / Concrete needs a long time dry - in worst

cases up to one year. Requirements, moisture content limits. For concrete sub

floors: max 2% moisture content

Note: All types of

cement screed/concrete/tiles sub floors require a moisture inhibitor - an

ageing resistant PE - plastic film, min. 0,20 mm thick. (sd - value - 100m)

overlapping minimum 15 cm under skirting board and tape all joints overlapping

300 mm. Our wood floors are dried to a moisture content of 8% + /– 2%. Measure

and record.

Note: Subfloor construction boards, for example

particle board/plywood at time of installation may have too high moisture

content (maximum acceptable is 14%). Measure and record all readings. Dry, if

necessary or replace with boards of correct moisture content. In ALL cases

using plywood / particle board an expansion gap of 3 mm should be left ALL round

EVERY board.

Flat: Measure always

with a straight edge. Unevenness of + 2 mm over 2M is unacceptable and should

be levelled.

Tip: Use a suitable

flooring compound to level your sub floor – never use foams or other soft

materials. Always check the floor afterwards for evenness.

Firm and Clean:

Concrete should always be firm and sound, if crumbly, cracked or soft remedial

work is required prior to installation of your Flooring. Always check old

wooden sub floor nail/screw fixings are sound to eliminate the possibility of

unevenness or squeaking. Brush or vacuum clean your sub floor prior to

installing - work clean!

3C) Underlay This type

of Engineered Flooring, when installed using a floating installation, must be

installed over a minimum of 2mm foam or poly underlay (with a density of a

minimum of 180kg/m³). If an acoustic underlay has been installed first and is

suitable according to manufacturer’s guidelines for the flooring to be laid

directly on top, then a 2mm foam or poly-type underlay is NOT necessary.

However, if a 1.5mm cork or bitumen type acoustic barrier is used, then 2mm

foam, in particular, is still recommended to install over the subfloor. The

foam also stops grinding between wood, OSB or plywood sub-floors and should be

used. Moisture inhibitors (such as 1000g Polythene) will only assist in

protecting the floor from residual moisture when the concrete subfloor is 2% or

less. An underlay or moisture inhibitor will NOT cover up an inherent moisture

problem that should have been addressed before installation of your engineered

wood floor.

Sound insulation

material must be installed (over the PE-plastic film, if so required). Use

flooring paper, 2mm cork, HD-foams (over 30 kg/m³) 2-3 mm or other approved

Underlay materials. Always check with your supplier for suitable product

selection.

3D) Underfloor Heating

When installing over Underfloor Heating, we recommend the following guidelines

should be followed;

• Maximum allowed

temperature on top of the floor underneath the floorboards is 29 °C. Please

note, it is not allowed to cover this wooden floor with carpets or rugs if

installed over a floor heating system.

• Always follow the

heating regulation recommendations given by the underfloor heating system

supplier.

4.

Installation Preparation

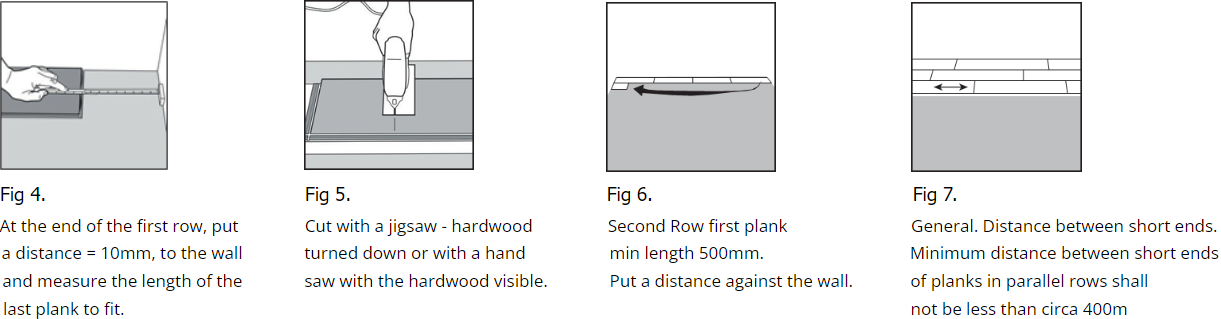

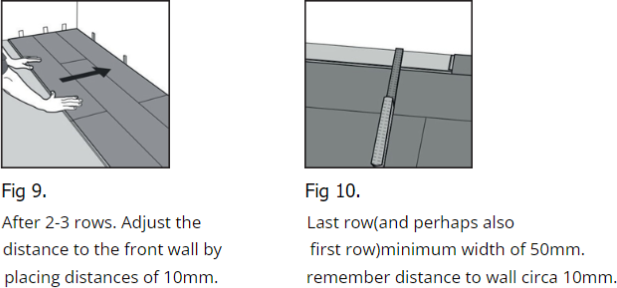

4A) General Measure

the area before installation and decide on the installation direction. It is

recommended to install the board’s end on to the primary source of light. The

width of the last row of boards should not be less than 50mm. If so, adjust the

width of the first board to compensate.

ALWAYS REMEMBER -

MEASURE TWICE & CUT ONCE!

In narrow

hallways/corridors, install the floor parallel to the longest walls. Claims of

visibly defective floorboards must be made before installation. Each board

should be inspected to ensure that the quality is acceptable. No warranty

claims relating to surface defects can be accepted after installation. If you

lay it, you have accepted it.

5.

Installation Method using Valinge 5G

Technology

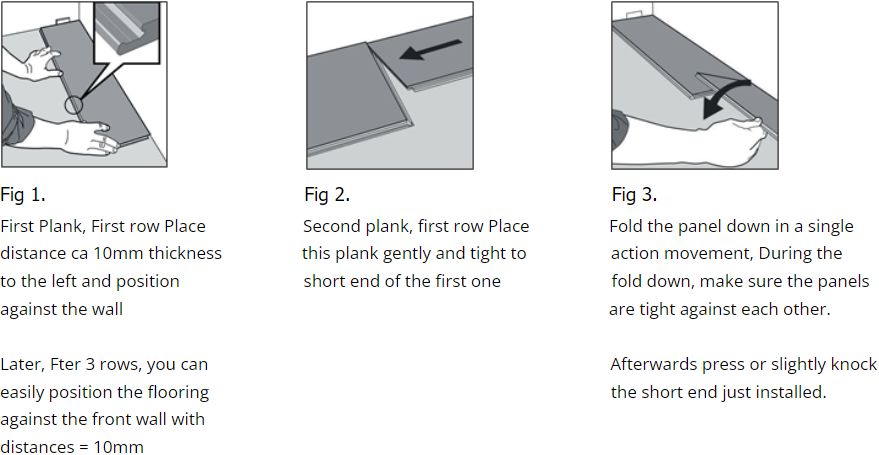

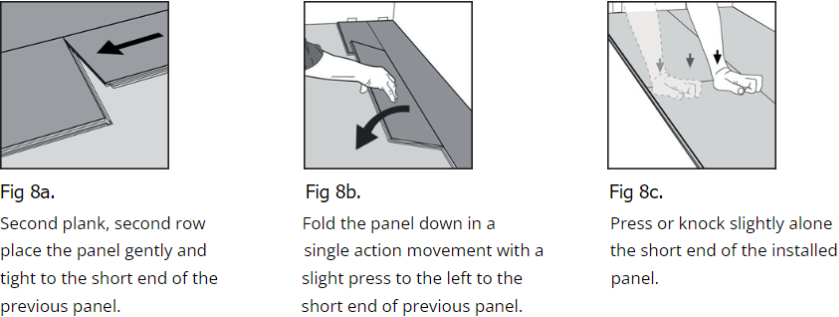

Install the first row as

shown in diagrams below, 2nd and following rows as per method 2: First only connect

board by board as in first row and then angle in the long side of the whole long

row into the 1st row. Tip: Connect this second row on top of the first and then

slowly slide the whole row towards you, till the groove falls in start position.

Angle in by lifting and pushing forward the whole row and fine tune the panel positions

with the positioning block as shown below (fig.6).

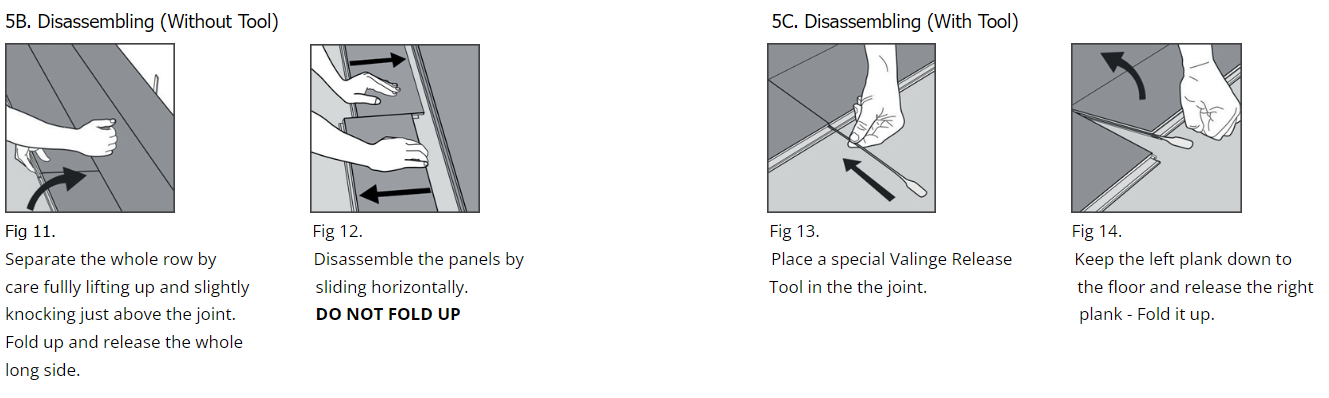

Others: Your floor can

very easily be disassembled, which enables replacement during installation and

also during use. See section F below. You can use the floor immediately after installation.

The skirting’s (moldings) must be fixed to the walls (never to the floor).

Instructions for installing wood floorings with a locking system based on the Vålinge 5G technology.

6.

After the Installation

Once the installation

is complete, the recommended relative humidity (RH) of 45-60 % and temperature

of 18-24°C in the room should be maintained at all times. If necessary, install

a humidifier/dehumidifier to ensure the best climate for yourself, your furniture

and your wood floor. If the environment is not suitably maintained or the floor

is not correctly installed as per these instructions, the floor may show small

gaps or some tension in the floor, which can be heard with footfall.

7.

Cleaning and maintenance

The floor should be cleaned

by using a vacuum cleaner using an attachment for wood floors or brushed using a

soft-bristled brush. If required, wipe with a damp-dry (well squeezed) cloth with

a mild soap. Any liquid accidentally spilt must be wiped off immediately to

prevent staining.

8.

Floor protection

It is recommended practice

to use a good quality doormat at every entrance (both inside and out) to ensure

dirt and dust particles aren't transferred onto the floor surface. For furniture,

soft protective pads should be applied to table and chair legs to avoid any damage

when moving furniture.

9.

Warranty

Your UKflooringcompany

5G LOC European Engineered Flooring warranty last for 20 years starting from the

date of purchase. Please refer to our warranty section at https://www.ukflooringcompany.com for

more detailed information.

%20(1000%20×%20700%20px)%20(1000%20×%20650%20px)%20(1000%20×%20670%20px)-700x500w.png)

128 Comment(s)

I always prefer to read the quality content and this thing I found in you post. I am really thank full for you for this post.

Stay ahead of the College of Contract Management's essential nec courses to further your career in construction. These extensive online courses offer the theoretical understanding and hands-on training required to oversee projects under NEC3 and NEC4 contracts. You'll gain the ability to implement best practices that are in line with globally accepted standards, which will improve your ability to manage building projects.

The learning platform provides systematically organized, objective-oriented educational content while maintaining accommodation for individual scheduling constraints. Participants submit written assessments to the College of Contract Management, functioning as the designated course administrator, for rics online cpd submission processing. This methodology permits adequate time for revisions subsequent to assessor review and commentary provision before final authorization. The program is optimally designed for professionals seeking competency advancement without professional departure. Participants should reference the college's website for essential submission and assessment timeframes pertaining to evaluation and interview requirements.

Thanks for sharing this valuable information with readers.

顶尖的Paper代写 http://www.pnstudy.com 机构会有一个专业、经验丰富的团队,他们拥有在相关领域的学位和经验。会保证文章的原创性,防止抄袭,并提供质量保障。

网课代修为学生提供了便捷灵活的学习方式,并带来了诸多益处。通过网课代修,学生能够更好地平衡学业和其他活动,获得更广阔的学习资源和优质的帮助,拓展更多的学习课程和专业选择。然而,学生在享受网课代修带来便利的同时,也要时刻保持学术诚信和自主思考的能力。让我们共同探索网课代修的无限可能,助力学生追求卓越的学习和成长。

Bangalore Escorts are professional companions who provide services to individuals seeking companionship or entertainment. These escorts are trained to cater to the needs and desires of their clients offering a range of services from dinner dates to intimate encounters

If you are looking for some fun and excitement in Saket then Saket Escorts are the perfect choice for you! These beautiful and charming ladies are ready to show you a good time and make your stay in Saket unforgettable.

Escorts in Delhi are individuals who provide companionship services to clients for a fee. They can accompany clients to social events dinners or simply spend time with them in private settings.

If you're looking for some fun and excitement in Goa why not consider hiring an escort? These professional companions can show you around the city accompany you to events or simply provide some company for a night out.

Delhi Escorts are individuals who provide companionship and social escort services in the city of Delhi. They are professionals who offer their services to clients who are looking for a date a companion for an event or just someone to spend time with.

Looking for some fun and excitement in Raipur? Well look no further because Raipur Escorts are here to spice up your life! Whether you're looking for a night out on the town or a cozy evening in these lovely ladies are ready to cater to your every need.

Looking for some fun and companionship in Bangalore? Well you're in luck because there are plenty of escorts in Bangalore ready to show you a good time! Whether you're looking for a night out on the town or just some one-on-one time these escorts can cater to your needs and provide you with a memorable experience.

Are you looking for some excitement in Delhi? Well look no further because Delhi Escorts Service is here to fulfill all your desires. Our beautiful and talented escorts are ready to provide you with a memorable experience that you will never forget.

If you're looking for a fun and exciting time in Delhi why not consider hiring an escort? Delhi is a bustling city with so much to see and do and having a local escort by your side can make your experience even better.

Independent escorts in Delhi are individuals who provide companionship services on their own terms without being affiliated with any agency. These escorts have the freedom to set their own schedules rates and boundaries giving them more control over their work.

The Vertu Smart Watch epitomizes luxury in wearable technology, seamlessly merging exquisite design with cutting-edge functionality. Crafted from high-quality materials such as stainless steel and sapphire crystal, each watch not only boasts a striking appearance but also ensures durability for everyday wear. This attention to detail reflects Vertu's commitment to artistry and sophistication, making the Vertu Smart Watch a true statement piece for those who appreciate the finer things in life.

我们理解留学生在学业上的压力,因此我们的代写服务不仅帮助你减轻负担,还能帮助你掌握学术写作的技巧与结构,让你在未来的学习中更加自信和从容。选择我们的代写留学生作业服务,你将获得一份高质量的学术作品,同时也能专注于其他重要的学习或生活任务。

The METAVERTU 2 FORTUNE FLAME 2024 DRAGON YEAR LUCKY EDITION is more than just a smartphone; it is a statement of Vertu's dedication to providing the pinnacle of luxury and technological sophistication. With its high-resolution display and superior processing power, this phone is a bridge to the blockchain universe, offering seamless access to cryptocurrencies, NFTs, and decentralized applications. It is designed for those who demand the best in life, combining the legacy of Vertu's craftsmanship with the future of digital interaction and wealth management, making it the ultimate accessory for the tech-savvy elite .

The METAWATCH H1 is a testament to Vertu's commitment to quality and craftsmanship. It boasts a 1.85-inch TFT screen with IPS technology, delivering a crisp and vibrant display. The watch is equipped with a professional sports module, heart rate monitoring, and blood oxygen monitoring, ensuring that it is not only a fashion statement but also a health and fitness companion. The METAWATCH H1 is protected by IP68 dust and water resistance, making it a durable choice for the active individual. Its sleek design, featuring a carbon fiber case and sapphire crystal, adds to its allure and durability .

Seeking a reliable SEO company in Stockholm for SEO optimization, online marketing, website design, Google Ads management, Social Media, USA, UK, Australia, UAE.

We provide support for those looking for 'Take my GED for me' or 'Take my TEAS exam' solutions. Need help with your GED or TEAS exam? We offer services so you can pay someone to take your GED or TEAS exam, hire someone for exam assistance and solutions

Leave a Comment