How to installatlion Laminate Click Flooring

%20(1800%20×%20600%20px)-1920x600w.png)

How to installatlion Laminate Click Flooring

For Urban 8mm and 12mm Laminate Flooring

A) Before Installation

Temperature and humidity conditions of the floor and areas where laminate flooring is to be installed: Temperature and humidity levels of the floor and areas where laminate flooring is to be installed must conform with suitable temperature and relative humidity conditions before installation, during installation and after the process. Laminate flooring must be kept for 48 hours before the installation to fit into the areas where the installation is to be made. (Temperature of the areas where the installation is to be made must be a minimum of +18°C. Floor temperature must be minimum +15°C. Relative humidity rate of the areas where the installation is to be made must be 40-70%). The surface of the floor where the installation is to be made; All surfaces on which laminate flooring is to be installed must be ready for the process, according to the technical conditions that must be considered.

Meet the below-specified conditions, during the floor is being checked:

- Make sure that the floor is completely dry.

- Check the surface flatness. (Fluctuation on the surface must be <2mm in a metre.)

- Check the floor hardness.

- Cleaning the surface of the floor where installation is to be made. (dust, dirt, etc.)

- Installation can be made on concrete or tiles as well

Laminate flooring can also be installed on the floors where water-circulation underfloor heating systems are used. In such a case, please use the craft paper instead of foam.

In addition to these, if electric underfloor heating systems (check the surface temperature) is placed in the cement or concrete layer (if the heating system is not above the concrete layer), it is suitable for installation. The surface temperature of the floor must not exceed maximum 28°C.

In case of getting the guarantee of the surface temperature of the floor will not exceed 28°C from company produces the underfloor heating system, use of adjustable plate heating systems might be allowed as to be used as installation floor. Standard plate-based electric underfloor heating systems available in the market cause the surface temperature to be much higher than 28°C, in case of excessive sudden heat changes. Because of that, it is not suitable as the installation floor.

Unsuitable floors are:

- Textile Material (Carpet, Rugs, etc.)

- PVC, Linoleum, Wood / Laminate Flooring etc.

- Must not be installed on wet surfaces such as toilets, bathrooms or saunas.

- In-vehicle indoor flooring.

Mandatory regulations for installation:

- PE form must be laid on covering all surfaces of floors for moisture insulations of the floor. For the purpose of ensuring sound, heat and moisture insulation in the floor and eliminating roughness of the floor (if less than 2mm), it must be laid parallel to the long side of laminate floor plans and try to cover all the floor installation. While laying the foam strips side by side, they must be laid in adjacent sides (by not leaving any open areas.)

- As laminate flooring is installed on the floor in a floating system, they are not screwed, nailed and not glued on the floor.

- During the installation, a distance of the joints of two short sides definitely must be at least 300mm. In case of products with a curved side and/or special pattern as manufactured by the factory (for example decor tile) you must apply by shifting equally according to the curved side and/or pattern.

- The distance between laminate flooring and fixed edges (walls, heater pipes, etc.) must be 15mm in installation areas.

- Laminate flooring must be installed maximum 10m to the length of the panels and maximum 8m to the width of the panels in installation areas. Transition profiles must be used in areas where these measurements exceed.

- Damaged or unusable panels must be eliminated before and during the installation.

- Our products are manufactured in multiple locations. Please pay attention to our products that are shipped from the same location before starting the installation. Please do not use the products from different locations in the same areas.

- Before starting the installation, please group all products on the bases of their production dates and start using installation preferring materials with the recent dates to each other within the same area.

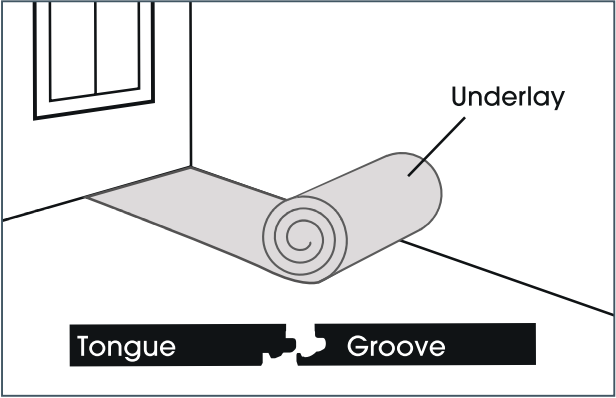

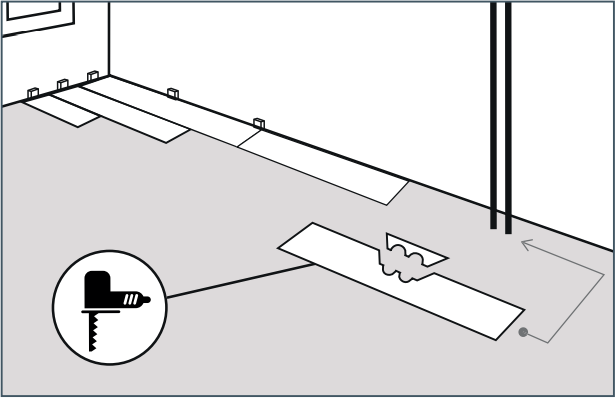

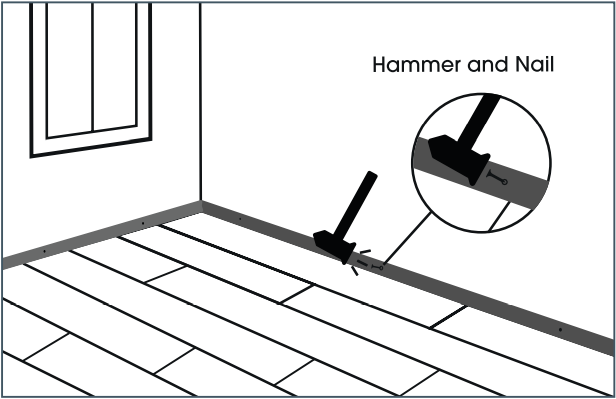

Fig.1

Place the underlay (foam) on the floor and check what tongue and groove profiles are.

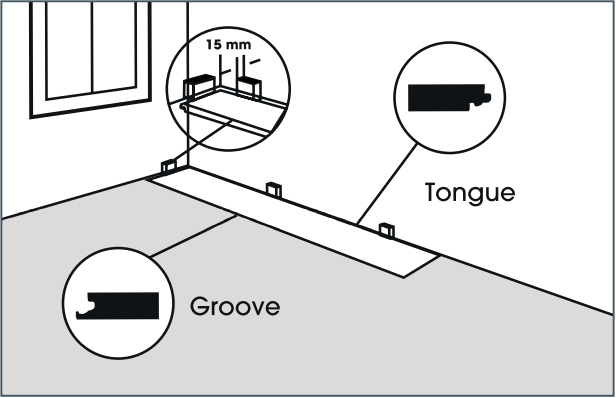

Fig. 2

Start the installation with the first line from the left corner of the room by meeting both tongues click sides or the panel to the wall.

While starting the installation, place the distance protector (a wedge of 15mm thickness) that ensures distance with the wall.

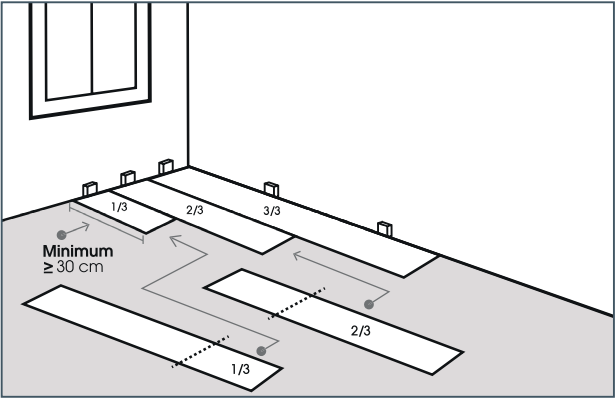

Fig. 3

Place a whole panel whose tongue sides of laminate flooring face the corner. After that cut 2/3 of another panel and connect it to the whole panel whose tongue click sides face the wall,

after that cut 1/3 of another laminate flooring, connect it next to the 2/3 of laminate flooring. So cut side of the 2/3, 1/3 of the panels face to the wall.

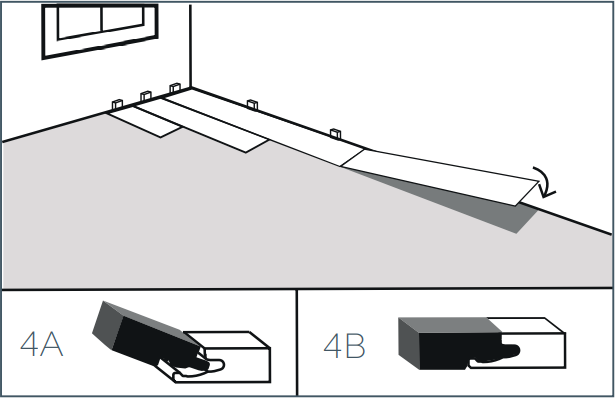

Fig. 4

To continue the created integrity, the tongue click of the panel's short side is placed on the groove click of the panel's short side to get

connected by 30 degrees angles and install by putting down to the floor. For details, please check Fig.4A & 4B)

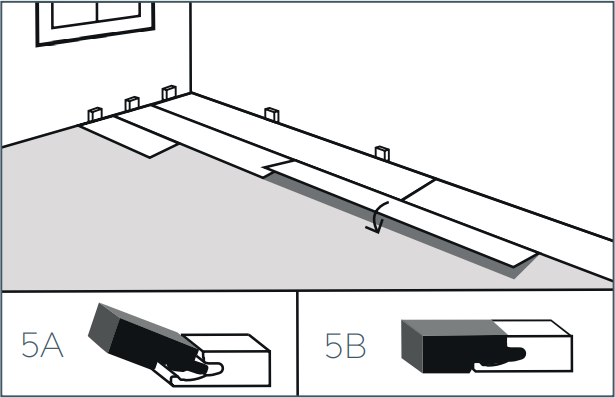

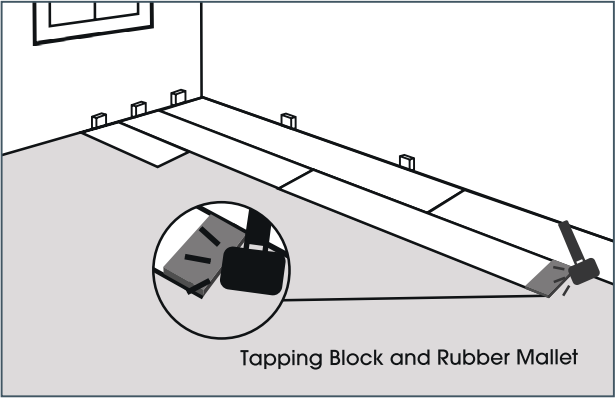

Fig. 5

During installation lock the long side of the panels. For details, please check Fig.5A & 5B.

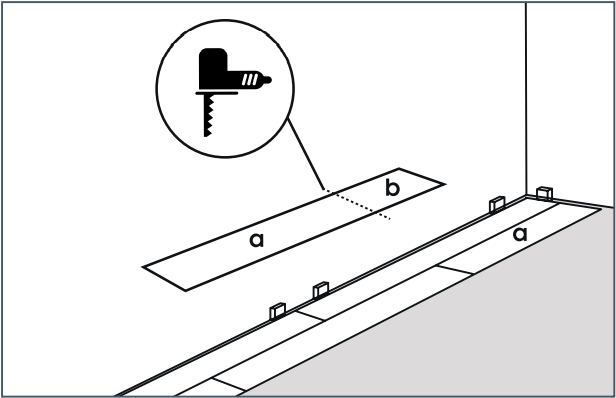

Fig. 6

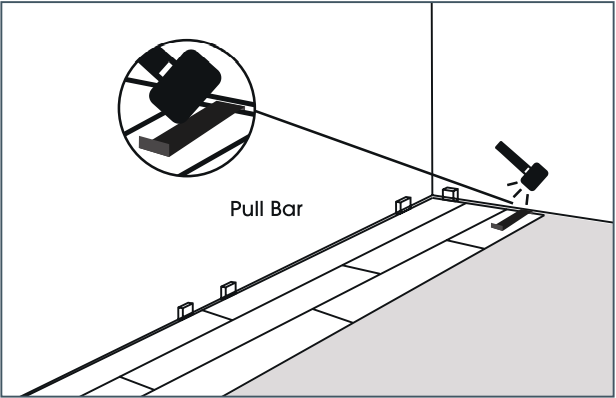

Fig. 7

Fig. 8

Fig. 9

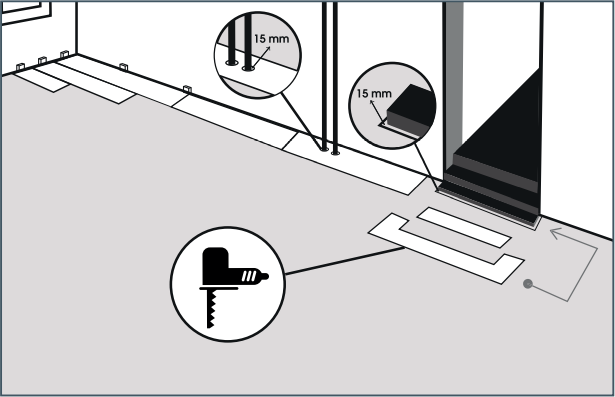

During the installation, cut the section on the panels which faces the heating pipes by having 15mm gap with fixed areas by convenient

cutting tools. The pieces which were cut are glued to each other with convenient adhesive.

Fig. 10

Laminate flooring is cut on the sides by having a minimum 15mm gap according to the stair step and fit them appropriately.

Fig. 11

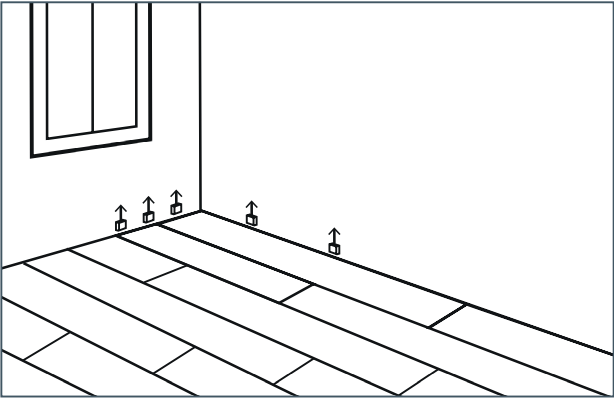

Remove all the wedges.

Fig. 12

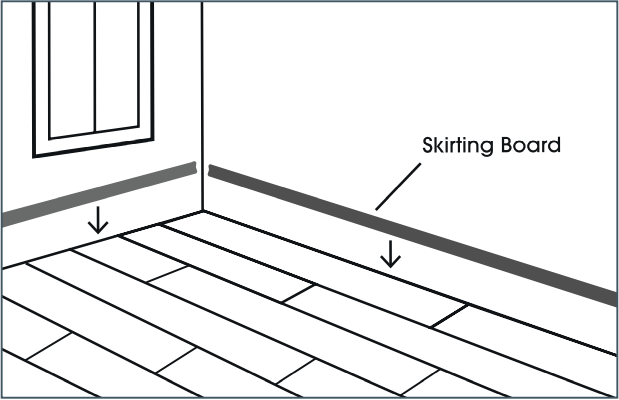

Skirting boards are cut depending on how they fit to be ready for installation.

Fig. 13

Skirting boards are cut depending on how they fit to be ready for installation.

C) After Installation

- Pieces of plastic or felt must be placed under the fixed of moving furniture legs.

- Please change locations of the heavy furniture by lifting.

- Furniture with wheels. ‘Couches and Seats’ wheels must be soft type.

- Please clean with a well-squeezed microfiber cloth that does not leave any residue, without letting laminate flooring’s surface wet. Our products have TSE Laminate Flooring Standards Certificate and meet the requirements of the relevant standard. Unless otherwise stated on our products, “They are not water-resistant and must be protected against exposure to water.”

- Do not use any abrasive cleaners.

- Do not sand the laminate flooring

%20(1000%20×%20700%20px)%20(1000%20×%20650%20px)%20(1000%20×%20670%20px)-700x500w.png)

382 Comment(s)

This is amazing. Thanks for sharing this blog. I have become a fan of your blogs. This blog is so interesting and informative.

Keep it on thank you for sharing

顶尖的英国代考 https://www.lunwentop.net/ying-guo-dai-kao/ 机构会有一个专业、经验丰富的团队,他们拥有在相关领域的学位和经验。会保证文章的原创性,防止抄袭,并提供质量保障。

无论您的学科、主题或最后期限是什么,我们都愿意帮助您完成Essay。我们98%以上的客户保持满意,因为我们从不吝惜我们的服务质量。我们的Essay代写平台是您仅有的正确选择! 我们的专家团队知道如何完成所有学术领域和学术水平的作业。

作为一名留学生,您是否因为各种学业任务搞到烦恼呢?好不容易解决了Essay,明天又有一个Assignment,周末之前又要完成一个Report!有了HotEssay您再也不用担心社交活动与繁重学业之间的冲突。无需繁琐的流畅,联系网站客服或者自助注册提交订单,我们专业的写手团队立即响应!欢迎您注册成为我们的用户,体验极致网课代修与留学代写服务!

The Vertu Signature Cobra is more than just a limited edition phone; it's a symbol of unrivaled prestige . Beyond its stunning appearance, it offers state-of-the-art technology and unparalleled craftsmanship. The device is powered by a high-performance processor, ensuring that its performance matches its aesthetic appeal. Vertu's concierge service is also at your disposal 24/7, ready to fulfill any request, from booking the most exclusive restaurants to securing tickets to sold-out events. It's an investment that not only provides connectivity but also a gateway to a world of luxury and personalized service.

Seeking a reliable SEO company in Stockholm for SEO optimization, online marketing, website design, Google Ads management, Social Media, USA, UK, Australia, UAE.

We provide support for those looking for 'Take my GED for me' or 'Take my TEAS exam' solutions. Need help with your GED or TEAS exam? We offer services so you can pay someone to take your GED or TEAS exam, hire someone for exam assistance and solutions

在学生的口吻来看,选择作业代写的理由也显而易见。留学生活充满了各种未知和挑战,适应一个全新的环境需要时间和精力。

Trò “Lucky Dice” của Pbv88 nhìn đơn giản nhưng ăn tiền không đơn giản. Cảm giác gieo xúc xắc xong tim như muốn rớt – thắng thì hét lên, thua cũng muốn gỡ liền tay.

Discover the best apartments in Rishikesh, offering modern amenities, panoramic Ganges & Himalayan views, and prime locations. Gated communities with 24/7 security ensure safety, while proximity to temples, markets, and riverfronts enhances convenience. Ideal for spiritual seekers and nature enthusiasts.

Do your critical air systems require the precision protection of an Original Atlas Copco Filter 9093003271 (MINI-FIL-08B-D)?

Contact Seadweer today! Get expert assistance, verify compatibility, and secure the authentic, high-quality components your Atlas Copco system needs for unparalleled reliability and performance. Trust Seadweer for all your genuine compressor parts.

"This guide is incredibly helpful for DIY enthusiasts! The step-by-step instructions and clear visuals make installing laminate click flooring straightforward. I especially appreciate the tips on acclimating the planks and ensuring proper expansion gaps. Looking forward to trying this out in my own home!"

For anyone new to online info, 오피사이트 is perfect.

주소타운’s design promotes fast and efficient browsing.

Nothing beats finding a new favorite 무료야동.

It's incredible how 오피 can transform a rough day into a peaceful one.

I was pleasantly surprised by the convenience of 다낭 환전 services available at our hotel.

<ahref="https://disposablecarts.co.uk/product/acapulco-gold-strain/" rel="dofollow">Acapulco Gold Strain</a>

<ahref="https://disposablecarts.co.uk/product/afghani-strain/" rel="dofollow">Afghani strain</a>

<ahref="https://disposablecarts.co.uk/product/ak-47-strain/" rel="dofollow">AK 47 Strain</a>

<ahref="https://disposablecarts.co.uk/product/amnesia-haze-strain/" rel="dofollow">Amnesia Haze Strain</a>

<ahref="https://disposablecarts.co.uk/product/blue-gelato-strain/" rel="dofollow">Blue Gelato Strain</a>

<ahref="https://disposablecarts.co.uk/product/blueberry-muffin-strain/" rel="dofollow">Blueberry Muffin Strain</a>

<ahref="https://disposablecarts.co.uk/product/bubblegum-popperz-strain/" rel="dofollow">Bubblegum Popperz Strain</a>

<ahref="https://disposablecarts.co.uk/product/chemdawg-strain/" rel="dofollow">Chemdawg Strain</a>

<ahref="https://disposablecarts.co.uk/product/diamond-dust-strain/" rel="dofollow">Diamond Dust Strain</a>

<ahref="https://disposablecarts.co.uk/product/gary-payton-strain/" rel="dofollow">Gary Payton Strain</a>

<ahref="https://disposablecarts.co.uk/product/miracle-alien-cookies-strain/" rel="dofollow">Miracle Alien Cookies Strain</a>

<ahref="https://disposablecarts.co.uk/product/og-kush/" rel="dofollow">OG Kush</a>

<ahref="https://disposablecarts.co.uk/product/permanent-marker-strain/" rel="dofollow">Permanent Marker Strain</a>

<ahref="https://disposablecarts.co.uk/product/zoapscotti-strain/" rel="dofollow">Zoapscotti Strain</a>

<ahref="https://disposablecarts.co.uk/product/blueberry-oil/" rel="dofollow">Blueberry Oil</a>

<ahref="https://disposablecarts.co.uk/product/co%e2%82%82-extract-oil/" rel="dofollow">CO₂ Extract Oil</a>

<ahref="https://disposablecarts.co.uk/product/delta-8-distillate/" rel="dofollow">Delta 8 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/d9-distillate/" rel="dofollow">Delta 9 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/delta-10-distillate/" rel="dofollow">DELTA-10 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/hhc-distillate/" rel="dofollow">HHC Distillate</a>

<ahref="https://disposablecarts.co.uk/product/live-resin-oil/" rel="dofollow">Live Resin Oil</a>

<ahref="https://disposablecarts.co.uk/product/purple-punch-oil/" rel="dofollow">Purple Punch oil</a>

<ahref="https://disposablecarts.co.uk/product/raw-pure-thc-oil/" rel="dofollow">Raw (Pure) THC Oil</a>

<ahref="https://disposablecarts.co.uk/product/rick-simpson-oil/" rel="dofollow">Rick Simpson Oil</a>

<ahref="https://disposablecarts.co.uk/product/thc-clear-distillate/" rel="dofollow">THC Clear Distillate</a>

<ahref="https://disposablecarts.co.uk/product/thc-d9-syrup/" rel="dofollow">THC Delta 9 Syrup</a>

<ahref="https://disposablecarts.co.uk/product/star-killer-oil/" rel="dofollow">THC Star Killer Oil</a>

<ahref="https://disposablecarts.co.uk/product/thca-distillate/" rel="dofollow">THCA Distillate</a>

<ahref="https://disposablecarts.co.uk/product/thcp-distillate-oil/" rel="dofollow">THCP Distillate Oil</a>

<ahref="https://disposablecarts.co.uk/product/whole-melt-extracts-2g-disposable/" rel="dofollow">Whole Melt Extracts 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/tre-house-hhc-live-resin-disposable-vape-pens-2grams/" rel="dofollow">Tre House HHC Live Resin Disposable Vape Pens (2grams)</a>

<ahref="https://disposablecarts.co.uk/product/the-wizard-of-terps-1ml-syringe/" rel="dofollow">The Wizard Of Terps 1ml Syringe</a>

<ahref="https://disposablecarts.co.uk/product/ruby-carts-disposable-vape-pen/" rel="dofollow">Ruby Carts Disposable Vape Pen</a>

<ahref="https://disposablecarts.co.uk/product/potent-disposable/" rel="dofollow">Potent disposable</a>

<ahref="https://disposablecarts.co.uk/product/packwoods-x-runtz/" rel="dofollow">Packwoods x Runtz</a>

<ahref="https://disposablecarts.co.uk/product/ace-ultra-premium-disposable/" rel="dofollow">Ace Ultra Premium Disposable</a>

<ahref="https://disposablecarts.co.uk/product/backpackboyz-carts/" rel="dofollow">Backpackboyz Carts</a>

<ahref="https://disposablecarts.co.uk/product/baked-bar-2g-disposable/" rel="dofollow">Baked Bar 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/burst-2g-disposable-vape/" rel="dofollow">Burst 2g Disposable Vape</a>

<ahref="https://disposablecarts.co.uk/product/cali-company-disposable-vape/" rel="dofollow">Cali Company Disposable Vape</a>

<ahref="https://disposablecarts.co.uk/product/choice-lab-2g-disposable/" rel="dofollow">Choice Lab 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/clean-carts-2g-disposable/" rel="dofollow">Clean Carts 2G Disposable</a>

<ahref="https://disposablecarts.co.uk/product/cookies-1g-disposable/" rel="dofollow">Cookies 1g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/family-high-range/" rel="dofollow">Family High Range</a>

<ahref="https://disposablecarts.co.uk/product/favorites-2g-disposable/" rel="dofollow">Favorites 2G Disposable</a>

<ahref="https://disposablecarts.co.uk/product/gassed-up-2g-disposable/" rel="dofollow">Gassed Up 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/jeeter-juice-carts/" rel="dofollow">Jeeter Juice Carts</a>

<ahref="https://disposablecarts.co.uk/product/jungle-boys-vape/" rel="dofollow">Jungle Boys Vape</a>

<ahref="https://disposablecarts.co.uk/product/seedless-disposable/" rel="dofollow">Seedless Disposable</a>

<ahref="https://englandtrap.com/product/apple-fritter-strain/" rel="dofollow">Apple Fritter Strain</a>

<ahref="https://englandtrap.com/product/biscotti-strain/" rel="dofollow">Biscotti Strain</a>

<ahref="https://englandtrap.com/product/blueberry-zkittlez-strain/" rel="dofollow">Blueberry Strain</a>

<ahref="https://englandtrap.com/product/cheese-kush/" rel="dofollow">Cheese strain</a>

<ahref="https://englandtrap.com/product/gelato-strain/" rel="dofollow">Gelato Strain</a>

<ahref="https://englandtrap.com/product/gg4-strain/" rel="dofollow">GG4 Strain</a>

<ahref="https://englandtrap.com/product/godfather-og-strain/" rel="dofollow">Godfather OG Strain</a>

<ahref="https://englandtrap.com/product/stardawg-strain/" rel="dofollow">Stardawg Strain</a>

<ahref="https://englandtrap.com/product/super-lemon-cherry-strain/" rel="dofollow">Super Lemon Cherry Strain</a>

<ahref="https://englandtrap.com/product/wedding-cake-strain-2/" rel="dofollow">Wedding Cake Strain</a>

<ahref="https://englandtrap.com/product/white-widow-strain/" rel="dofollow">White Widow Strain</a>

<ahref="https://englandtrap.com/product/girl-scout-cookies/" rel="dofollow">Girl Scout Cookies</a>

<ahref="https://englandtrap.com/product/granddaddy-purple-gdp-strain/" rel="dofollow">Granddaddy Purple Strain</a>

<ahref="https://englandtrap.com/product/ice-cream-cake-strain/" rel="dofollow">Ice Cream Cake Strain</a>

<ahref="https://englandtrap.com/product/master-kush/" rel="dofollow">Master Kush</a>

<ahref="https://englandtrap.com/product/northern-lights/" rel="dofollow">Northern Lights strain</a>

<ahref="https://englandtrap.com/product/skywalker-kush/" rel="dofollow">Skywalker Kush</a>

<ahref="https://englandtrap.com/product/watermelon-gelato-strain/" rel="dofollow">Watermelon Gelato Strain</a>

<ahref="https://englandtrap.com/product/zeus-og-strain/" rel="dofollow">Zeus OG Strain</a>

<ahref="https://englandtrap.com/product/amnesia-haze/" rel="dofollow">Amnesia Haze</a>

<ahref="https://englandtrap.com/product/bruce-banner-strain/" rel="dofollow">Bruce Banner Strain</a>

<ahref="https://englandtrap.com/product/durban-poison/" rel="dofollow">Durban Poison</a>

<ahref="https://englandtrap.com/product/guava-weed-strain/" rel="dofollow">Guava Weed Strain</a>

<ahref="https://englandtrap.com/product/maui-wowie-strain/" rel="dofollow">Maui Wowie Strain</a>

<ahref="https://englandtrap.com/product/mimosa-strain/" rel="dofollow">Mimosa Strain</a>

<ahref="https://englandtrap.com/product/sour-diesel-strain/" rel="dofollow">Sour Diesel Strain</a>

<ahref="https://englandtrap.com/product/super-silver-haze/" rel="dofollow">Super Silver Haze</a>

<ahref="https://englandtrap.com/product/big-chief-carts/" rel="dofollow">Big Chief Carts</a>

<ahref="https://englandtrap.com/product/cake-vape-pen/" rel="dofollow">CAKE VAPE PEN</a>

<ahref="https://englandtrap.com/product/cali-company-1g-vapes/" rel="dofollow">Cali Company 1g Vapes</a>

<ahref="https://englandtrap.com/product/dope-disposable-vape-pens/" rel="dofollow">Dope Disposable Vape Pens</a>

<ahref="https://englandtrap.com/product/england-trap-1g-vape/" rel="dofollow">England Trap 1g Vape</a>

<ahref="https://englandtrap.com/product/expensive-sht-vapes/" rel="dofollow">Expensive Sh*t Vapes</a>

<ahref="https://englandtrap.com/product/fryd-vape/" rel="dofollow">FRYD VAPE</a>

<ahref="https://englandtrap.com/product/muha-meds-vape/" rel="dofollow">Muha Meds Vape</a>

<ahref="https://englandtrap.com/product/packman-vape/" rel="dofollow">PACKMAN VAPE</a>

<ahref="https://englandtrap.com/product/packwoods-vape/" rel="dofollow">PACKWOODS VAPE</a>

<ahref="https://hashclinicc.com/product/alien-og-hash/" rel="dofollow">Alien OG hash</a>

<ahref="https://hashclinicc.com/product/cali-plates-hash/" rel="dofollow">Cali Plates Hash</a>

<ahref="https://hashclinicc.com/product/fly-farm-hash/" rel="dofollow">FLY FARM HASH</a>

<ahref="https://hashclinicc.com/product/kilogrammes-farm-hash/" rel="dofollow">Kilogrammes Farm Hash</a>

<ahref="https://hashclinicc.com/product/la-mousse-hash/" rel="dofollow">La Mousse Hash</a>

<ahref="https://hashclinicc.com/product/lemon-haze-hash/" rel="dofollow">LEMON HAZE HASH</a>

<ahref="https://hashclinicc.com/product/pollen-hash/" rel="dofollow">POLLEN HASH</a>

<ahref="https://hashclinicc.com/product/static-room-hash/" rel="dofollow">Static Room Hash</a>

<ahref="https://hashclinicc.com/product/tangie-hash/" rel="dofollow">TANGIE HASH</a>

<ahref="https://hashclinicc.com/product/wazabi-hash/" rel="dofollow">WAZABI HASH</a>

<ahref="https://hashclinicc.com/product/41-unicornz-strain/" rel="dofollow">41 Unicornz Strain</a>

<ahref="https://hashclinicc.com/product/apple-fritter-strain/" rel="dofollow">Apple Fritter Strain</a>

<ahref="https://hashclinicc.com/product/biscotti-strain/" rel="dofollow">Biscotti Strain</a>

<ahref="https://hashclinicc.com/product/blue-gelato-strain/" rel="dofollow">Blue Gelato Strain</a>

<ahref="https://hashclinicc.com/product/blueberry-muffin-strain/" rel="dofollow">Blueberry Muffin Strain</a>

<ahref="https://hashclinicc.com/product/bubblegum-popperz-strain/" rel="dofollow">Bubblegum Popperz Strain</a>

<ahref="https://hashclinicc.com/product/gary-payton-strain/" rel="dofollow">Gary Payton Strain</a>

<ahref="https://hashclinicc.com/product/hella-jelly-strain/" rel="dofollow">Hella Jelly Strain</a>

<ahref="https://hashclinicc.com/product/kosher-kush-strain/" rel="dofollow">Kosher Kush Strain</a>

<ahref="https://hashclinicc.com/product/lava-cake-strain/" rel="dofollow">Lava Cake Strain</a>

<ahref="https://hashclinicc.com/product/miracle-alien-cookies-strain/" rel="dofollow">Miracle Alien Cookies Strain</a>

<ahref="https://hashclinicc.com/product/moonrock-pre-roll/" rel="dofollow">Moonrock Pre Roll</a>

<ahref="https://hashclinicc.com/product/og-kush/" rel="dofollow">OG Kush</a>

<ahref="https://hashclinicc.com/product/tropical-runtz-strain/" rel="dofollow">Tropical runtz strain</a>

<ahref="https://hashclinicc.com/product/watermelon-runtz-strain/" rel="dofollow">Watermelon Runtz Strain</a>

<ahref="https://hashclinicc.com/product/backpackboyz-cart/" rel="dofollow">Backpackboyz Cart</a>

<ahref="https://hashclinicc.com/product/baked-bar-disposable/" rel="dofollow">Baked Bar Disposable</a>

<ahref="https://hashclinicc.com/product/cali-plug-disposable-vape/" rel="dofollow">Cali Plug Disposable Vape</a>

<ahref="https://hashclinicc.com/product/clean-carts-2g-disposable/" rel="dofollow">Clean Carts 2G Disposable</a>

<ahref="https://hashclinicc.com/product/d9-distillate/" rel="dofollow">D9 Distillate</a>

<ahref="https://hashclinicc.com/product/elites-switch-1g-disposable/" rel="dofollow">Elites Switch 1g Disposable</a>

<ahref="https://hashclinicc.com/product/expensive-shit-1g-vape/" rel="dofollow">Expensive Shit 1g Vape</a>

<ahref="https://hashclinicc.com/product/fryd-donuts-disposable-2g/" rel="dofollow">Fryd Donuts Disposable (2g)</a>

<ahref="https://hashclinicc.com/product/gassed-up-2g-disposable/" rel="dofollow">Gassed Up 2g Disposable</a>

<ahref="https://hashclinicc.com/product/jungle-boys-vape/" rel="dofollow">Jungle Boys Vape</a>

<ahref="https://hashclinicc.com/product/kushy-punch-disposable/" rel="dofollow">Kushy Punch Disposable</a>

<ahref="https://hashclinicc.com/product/melt-x-packwoods/" rel="dofollow">Melt X Packwoods</a>

<ahref="https://hashclinicc.com/product/packspod-vape/" rel="dofollow">Packspod Vape</a>

<ahref="https://hashclinicc.com/product/the-cali-company-disposable-vape/" rel="dofollow">The Cali company disposable vape</a>

<ahref="https://hashclinicc.com/product/tyson-pod-1000mg/" rel="dofollow">Tyson Pod 1000mg</a>

<ahref="https://disposablecarts.co.uk/product/acapulco-gold-strain/" rel="dofollow">Acapulco Gold Strain</a>

<ahref="https://disposablecarts.co.uk/product/afghani-strain/" rel="dofollow">Afghani strain</a>

<ahref="https://disposablecarts.co.uk/product/ak-47-strain/" rel="dofollow">AK 47 Strain</a>

<ahref="https://disposablecarts.co.uk/product/amnesia-haze-strain/" rel="dofollow">Amnesia Haze Strain</a>

<ahref="https://disposablecarts.co.uk/product/blue-gelato-strain/" rel="dofollow">Blue Gelato Strain</a>

<ahref="https://disposablecarts.co.uk/product/blueberry-muffin-strain/" rel="dofollow">Blueberry Muffin Strain</a>

<ahref="https://disposablecarts.co.uk/product/bubblegum-popperz-strain/" rel="dofollow">Bubblegum Popperz Strain</a>

<ahref="https://disposablecarts.co.uk/product/chemdawg-strain/" rel="dofollow">Chemdawg Strain</a>

<ahref="https://disposablecarts.co.uk/product/diamond-dust-strain/" rel="dofollow">Diamond Dust Strain</a>

<ahref="https://disposablecarts.co.uk/product/gary-payton-strain/" rel="dofollow">Gary Payton Strain</a>

<ahref="https://disposablecarts.co.uk/product/miracle-alien-cookies-strain/" rel="dofollow">Miracle Alien Cookies Strain</a>

<ahref="https://disposablecarts.co.uk/product/og-kush/" rel="dofollow">OG Kush</a>

<ahref="https://disposablecarts.co.uk/product/permanent-marker-strain/" rel="dofollow">Permanent Marker Strain</a>

<ahref="https://disposablecarts.co.uk/product/zoapscotti-strain/" rel="dofollow">Zoapscotti Strain</a>

<ahref="https://disposablecarts.co.uk/product/blueberry-oil/" rel="dofollow">Blueberry Oil</a>

<ahref="https://disposablecarts.co.uk/product/co%e2%82%82-extract-oil/" rel="dofollow">CO₂ Extract Oil</a>

<ahref="https://disposablecarts.co.uk/product/delta-8-distillate/" rel="dofollow">Delta 8 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/d9-distillate/" rel="dofollow">Delta 9 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/delta-10-distillate/" rel="dofollow">DELTA-10 Distillate</a>

<ahref="https://disposablecarts.co.uk/product/hhc-distillate/" rel="dofollow">HHC Distillate</a>

<ahref="https://disposablecarts.co.uk/product/live-resin-oil/" rel="dofollow">Live Resin Oil</a>

<ahref="https://disposablecarts.co.uk/product/purple-punch-oil/" rel="dofollow">Purple Punch oil</a>

<ahref="https://disposablecarts.co.uk/product/raw-pure-thc-oil/" rel="dofollow">Raw (Pure) THC Oil</a>

<ahref="https://disposablecarts.co.uk/product/rick-simpson-oil/" rel="dofollow">Rick Simpson Oil</a>

<ahref="https://disposablecarts.co.uk/product/thc-clear-distillate/" rel="dofollow">THC Clear Distillate</a>

<ahref="https://disposablecarts.co.uk/product/thc-d9-syrup/" rel="dofollow">THC Delta 9 Syrup</a>

<ahref="https://disposablecarts.co.uk/product/star-killer-oil/" rel="dofollow">THC Star Killer Oil</a>

<ahref="https://disposablecarts.co.uk/product/thca-distillate/" rel="dofollow">THCA Distillate</a>

<ahref="https://disposablecarts.co.uk/product/thcp-distillate-oil/" rel="dofollow">THCP Distillate Oil</a>

<ahref="https://disposablecarts.co.uk/product/whole-melt-extracts-2g-disposable/" rel="dofollow">Whole Melt Extracts 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/tre-house-hhc-live-resin-disposable-vape-pens-2grams/" rel="dofollow">Tre House HHC Live Resin Disposable Vape Pens (2grams)</a>

<ahref="https://disposablecarts.co.uk/product/the-wizard-of-terps-1ml-syringe/" rel="dofollow">The Wizard Of Terps 1ml Syringe</a>

<ahref="https://disposablecarts.co.uk/product/ruby-carts-disposable-vape-pen/" rel="dofollow">Ruby Carts Disposable Vape Pen</a>

<ahref="https://disposablecarts.co.uk/product/potent-disposable/" rel="dofollow">Potent disposable</a>

<ahref="https://disposablecarts.co.uk/product/packwoods-x-runtz/" rel="dofollow">Packwoods x Runtz</a>

<ahref="https://disposablecarts.co.uk/product/ace-ultra-premium-disposable/" rel="dofollow">Ace Ultra Premium Disposable</a>

<ahref="https://disposablecarts.co.uk/product/backpackboyz-carts/" rel="dofollow">Backpackboyz Carts</a>

<ahref="https://disposablecarts.co.uk/product/baked-bar-2g-disposable/" rel="dofollow">Baked Bar 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/burst-2g-disposable-vape/" rel="dofollow">Burst 2g Disposable Vape</a>

<ahref="https://disposablecarts.co.uk/product/cali-company-disposable-vape/" rel="dofollow">Cali Company Disposable Vape</a>

<ahref="https://disposablecarts.co.uk/product/choice-lab-2g-disposable/" rel="dofollow">Choice Lab 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/clean-carts-2g-disposable/" rel="dofollow">Clean Carts 2G Disposable</a>

<ahref="https://disposablecarts.co.uk/product/cookies-1g-disposable/" rel="dofollow">Cookies 1g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/family-high-range/" rel="dofollow">Family High Range</a>

<ahref="https://disposablecarts.co.uk/product/favorites-2g-disposable/" rel="dofollow">Favorites 2G Disposable</a>

<ahref="https://disposablecarts.co.uk/product/gassed-up-2g-disposable/" rel="dofollow">Gassed Up 2g Disposable</a>

<ahref="https://disposablecarts.co.uk/product/jeeter-juice-carts/" rel="dofollow">Jeeter Juice Carts</a>

<ahref="https://disposablecarts.co.uk/product/jungle-boys-vape/" rel="dofollow">Jungle Boys Vape</a>

<ahref="https://disposablecarts.co.uk/product/seedless-disposable/" rel="dofollow">Seedless Disposable</a>

<ahref="https://englandtrap.com/product/apple-fritter-strain/" rel="dofollow">Apple Fritter Strain</a>

<ahref="https://englandtrap.com/product/biscotti-strain/" rel="dofollow">Biscotti Strain</a>

<ahref="https://englandtrap.com/product/blueberry-zkittlez-strain/" rel="dofollow">Blueberry Strain</a>

<ahref="https://englandtrap.com/product/cheese-kush/" rel="dofollow">Cheese strain</a>

<ahref="https://englandtrap.com/product/gelato-strain/" rel="dofollow">Gelato Strain</a>

<ahref="https://englandtrap.com/product/gg4-strain/" rel="dofollow">GG4 Strain</a>

<ahref="https://englandtrap.com/product/godfather-og-strain/" rel="dofollow">Godfather OG Strain</a>

<ahref="https://englandtrap.com/product/stardawg-strain/" rel="dofollow">Stardawg Strain</a>

<ahref="https://englandtrap.com/product/super-lemon-cherry-strain/" rel="dofollow">Super Lemon Cherry Strain</a>

<ahref="https://englandtrap.com/product/wedding-cake-strain-2/" rel="dofollow">Wedding Cake Strain</a>

<ahref="https://englandtrap.com/product/white-widow-strain/" rel="dofollow">White Widow Strain</a>

<ahref="https://englandtrap.com/product/girl-scout-cookies/" rel="dofollow">Girl Scout Cookies</a>

<ahref="https://englandtrap.com/product/granddaddy-purple-gdp-strain/" rel="dofollow">Granddaddy Purple Strain</a>

<ahref="https://englandtrap.com/product/ice-cream-cake-strain/" rel="dofollow">Ice Cream Cake Strain</a>

<ahref="https://englandtrap.com/product/master-kush/" rel="dofollow">Master Kush</a>

<ahref="https://englandtrap.com/product/northern-lights/" rel="dofollow">Northern Lights strain</a>

<ahref="https://englandtrap.com/product/skywalker-kush/" rel="dofollow">Skywalker Kush</a>

<ahref="https://englandtrap.com/product/watermelon-gelato-strain/" rel="dofollow">Watermelon Gelato Strain</a>

<ahref="https://englandtrap.com/product/zeus-og-strain/" rel="dofollow">Zeus OG Strain</a>

<ahref="https://englandtrap.com/product/amnesia-haze/" rel="dofollow">Amnesia Haze</a>

<ahref="https://englandtrap.com/product/bruce-banner-strain/" rel="dofollow">Bruce Banner Strain</a>

<ahref="https://englandtrap.com/product/durban-poison/" rel="dofollow">Durban Poison</a>

<ahref="https://englandtrap.com/product/guava-weed-strain/" rel="dofollow">Guava Weed Strain</a>

<ahref="https://englandtrap.com/product/maui-wowie-strain/" rel="dofollow">Maui Wowie Strain</a>

<ahref="https://englandtrap.com/product/mimosa-strain/" rel="dofollow">Mimosa Strain</a>

<ahref="https://englandtrap.com/product/sour-diesel-strain/" rel="dofollow">Sour Diesel Strain</a>

<ahref="https://englandtrap.com/product/super-silver-haze/" rel="dofollow">Super Silver Haze</a>

<ahref="https://englandtrap.com/product/big-chief-carts/" rel="dofollow">Big Chief Carts</a>

<ahref="https://englandtrap.com/product/cake-vape-pen/" rel="dofollow">CAKE VAPE PEN</a>

<ahref="https://englandtrap.com/product/cali-company-1g-vapes/" rel="dofollow">Cali Company 1g Vapes</a>

<ahref="https://englandtrap.com/product/dope-disposable-vape-pens/" rel="dofollow">Dope Disposable Vape Pens</a>

<ahref="https://englandtrap.com/product/england-trap-1g-vape/" rel="dofollow">England Trap 1g Vape</a>

<ahref="https://englandtrap.com/product/expensive-sht-vapes/" rel="dofollow">Expensive Sh*t Vapes</a>

<ahref="https://englandtrap.com/product/fryd-vape/" rel="dofollow">FRYD VAPE</a>

<ahref="https://englandtrap.com/product/muha-meds-vape/" rel="dofollow">Muha Meds Vape</a>

<ahref="https://englandtrap.com/product/packman-vape/" rel="dofollow">PACKMAN VAPE</a>

<ahref="https://englandtrap.com/product/packwoods-vape/" rel="dofollow">PACKWOODS VAPE</a>

<ahref="https://hashclinicc.com/product/alien-og-hash/" rel="dofollow">Alien OG hash</a>

<ahref="https://hashclinicc.com/product/cali-plates-hash/" rel="dofollow">Cali Plates Hash</a>

<ahref="https://hashclinicc.com/product/fly-farm-hash/" rel="dofollow">FLY FARM HASH</a>

<ahref="https://hashclinicc.com/product/kilogrammes-farm-hash/" rel="dofollow">Kilogrammes Farm Hash</a>

<ahref="https://hashclinicc.com/product/la-mousse-hash/" rel="dofollow">La Mousse Hash</a>

<ahref="https://hashclinicc.com/product/lemon-haze-hash/" rel="dofollow">LEMON HAZE HASH</a>

<ahref="https://hashclinicc.com/product/pollen-hash/" rel="dofollow">POLLEN HASH</a>

<ahref="https://hashclinicc.com/product/static-room-hash/" rel="dofollow">Static Room Hash</a>

<ahref="https://hashclinicc.com/product/tangie-hash/" rel="dofollow">TANGIE HASH</a>

<ahref="https://hashclinicc.com/product/wazabi-hash/" rel="dofollow">WAZABI HASH</a>

<ahref="https://hashclinicc.com/product/41-unicornz-strain/" rel="dofollow">41 Unicornz Strain</a>

<ahref="https://hashclinicc.com/product/apple-fritter-strain/" rel="dofollow">Apple Fritter Strain</a>

<ahref="https://hashclinicc.com/product/biscotti-strain/" rel="dofollow">Biscotti Strain</a>

<ahref="https://hashclinicc.com/product/blue-gelato-strain/" rel="dofollow">Blue Gelato Strain</a>

<ahref="https://hashclinicc.com/product/blueberry-muffin-strain/" rel="dofollow">Blueberry Muffin Strain</a>

<ahref="https://hashclinicc.com/product/bubblegum-popperz-strain/" rel="dofollow">Bubblegum Popperz Strain</a>

<ahref="https://hashclinicc.com/product/gary-payton-strain/" rel="dofollow">Gary Payton Strain</a>

<ahref="https://hashclinicc.com/product/hella-jelly-strain/" rel="dofollow">Hella Jelly Strain</a>

<ahref="https://hashclinicc.com/product/kosher-kush-strain/" rel="dofollow">Kosher Kush Strain</a>

<ahref="https://hashclinicc.com/product/lava-cake-strain/" rel="dofollow">Lava Cake Strain</a>

<ahref="https://hashclinicc.com/product/miracle-alien-cookies-strain/" rel="dofollow">Miracle Alien Cookies Strain</a>

<ahref="https://hashclinicc.com/product/moonrock-pre-roll/" rel="dofollow">Moonrock Pre Roll</a>

<ahref="https://hashclinicc.com/product/og-kush/" rel="dofollow">OG Kush</a>

<ahref="https://hashclinicc.com/product/tropical-runtz-strain/" rel="dofollow">Tropical runtz strain</a>

<ahref="https://hashclinicc.com/product/watermelon-runtz-strain/" rel="dofollow">Watermelon Runtz Strain</a>

<ahref="https://hashclinicc.com/product/backpackboyz-cart/" rel="dofollow">Backpackboyz Cart</a>

<ahref="https://hashclinicc.com/product/baked-bar-disposable/" rel="dofollow">Baked Bar Disposable</a>

<ahref="https://hashclinicc.com/product/cali-plug-disposable-vape/" rel="dofollow">Cali Plug Disposable Vape</a>

<ahref="https://hashclinicc.com/product/clean-carts-2g-disposable/" rel="dofollow">Clean Carts 2G Disposable</a>

<ahref="https://hashclinicc.com/product/d9-distillate/" rel="dofollow">D9 Distillate</a>

<ahref="https://hashclinicc.com/product/elites-switch-1g-disposable/" rel="dofollow">Elites Switch 1g Disposable</a>

<ahref="https://hashclinicc.com/product/expensive-shit-1g-vape/" rel="dofollow">Expensive Shit 1g Vape</a>

<ahref="https://hashclinicc.com/product/fryd-donuts-disposable-2g/" rel="dofollow">Fryd Donuts Disposable (2g)</a>

<ahref="https://hashclinicc.com/product/gassed-up-2g-disposable/" rel="dofollow">Gassed Up 2g Disposable</a>

<ahref="https://hashclinicc.com/product/jungle-boys-vape/" rel="dofollow">Jungle Boys Vape</a>

<ahref="https://hashclinicc.com/product/kushy-punch-disposable/" rel="dofollow">Kushy Punch Disposable</a>

<ahref="https://hashclinicc.com/product/melt-x-packwoods/" rel="dofollow">Melt X Packwoods</a>

<ahref="https://hashclinicc.com/product/packspod-vape/" rel="dofollow">Packspod Vape</a>

<ahref="https://hashclinicc.com/product/the-cali-company-disposable-vape/" rel="dofollow">The Cali company disposable vape</a>

<ahref="https://hashclinicc.com/product/tyson-pod-1000mg/" rel="dofollow">Tyson Pod 1000mg</a>

Leave a Comment