Things you may want to know

02 Dec

20 Comment(s)

241197 View(s)

Hardwood flooring is a beautiful and unique product of nature, which is characterized by distinctive variations in grain and colors. These natural variations in color and grain are not flaws but are a part of the natural beauty and uniqueness of hardwood flooring. These inherent variations should be expected and serve to enhance the natural beauty and enduring charm. Our floorings are manufactured in accordance with accepted industry standards, which permit a defect tolerance not to exceed 5%. The defects may be of a manufacturing or natural type.

Before we head to the installation... Things you need to know...

Job site Inspection& Acclimation

- This type of real wood flooring

can be installed below, equal or above

ground level. Do not install

in a bathroom.

- In a new construction, hardwood flooring should be one of the last items installed. All work involving water or moisture (plumbing, acoustical ceilings, dry wall taping, etc.) should be completed prior to wood flooring being installed. Heating and air systems should be fully operating maintaining a consistent room temperature at 16°C to 27°C (60-80° F) and a constant relative humidity of 40% to 55%.

- Flooring

should not be delivered until the building has been closed in and cement work,

plastering, painting and other materials are completely dry. Concrete and plaster should be cured

and at least 60 days old.

Check basements and under-floor crawl space to be sure that they are dry and

well ventilated to avoid damage caused by moisture.

- Handle

with care. Do not stand on ends. Store our flooring in a dry place being sure to provide

at least a four-inch air space under and around cartons.

- Do not store

directly on concrete or near outside

walls. Cartons should

be placed in the installation

area.

- The humidity level of the house must be maintained between 40 % and 55 % all year long. Wood is a living product which reacts to humidity level variations. During summer, where the humidity level is at its highest point, the wood has a natural expansion and absorbs the humidity, these variations must be dealt with adequate dehumidification. As for winter, when the heating system is working, the humidity level is lower. It is then recommended to use a humidifier to minimise the extreme effects of shrinkage.

Subfloor conditions

- Clean- Scraped or sanded, swept, free of wax, grease, paint, oil and other debris.

- Horizontal/ Flat- Maximum tolerance of 5mm over 3m(3/16'' over 10') or 3mm over 2m(1/8'' over6')

- Sand high areas or joints.

If the floor is glued,

fill the fill low areas with a latex additive

cement surfacing product with a minimum resistance to compression of 20

000 kPa.

- Concrete

Slabs (regardless of existing floor covering): Use an approved calibrated

concrete Moisture Meter as a preliminary measurement for moisture. Concrete

subfloors must be finished at least 30 days before performing a test. Acceptable verification methods: Perform a polyfilm

test. Tape down 2’ x 2’ polyfilm

squares (a clear garbage bag or plastic drop cloth will do) in several places

on the floor. Wait 24-48 hours, and then check for the appearance of condensation

on the inside of the bag or plastic for a darkening on the concrete subfloor.

Either occurrence signals the likely presence of excess moisture, which needs

other measures with the concrete moisture meter Tramex. The measure must not

climb over 4,5 on the superior graduation. The floor can be glued directly on

concrete with a compression resistance of at least 20 000 kPa (3 000 lb/in2).

- Wood Substrates: Test the moisture of the wood substrate using a calibrated moisture meter approved for testing wood moisture according to the meter manufacturer. The reading should not exceed 12%, or read more than a 4% difference than moisture content of products being installed.

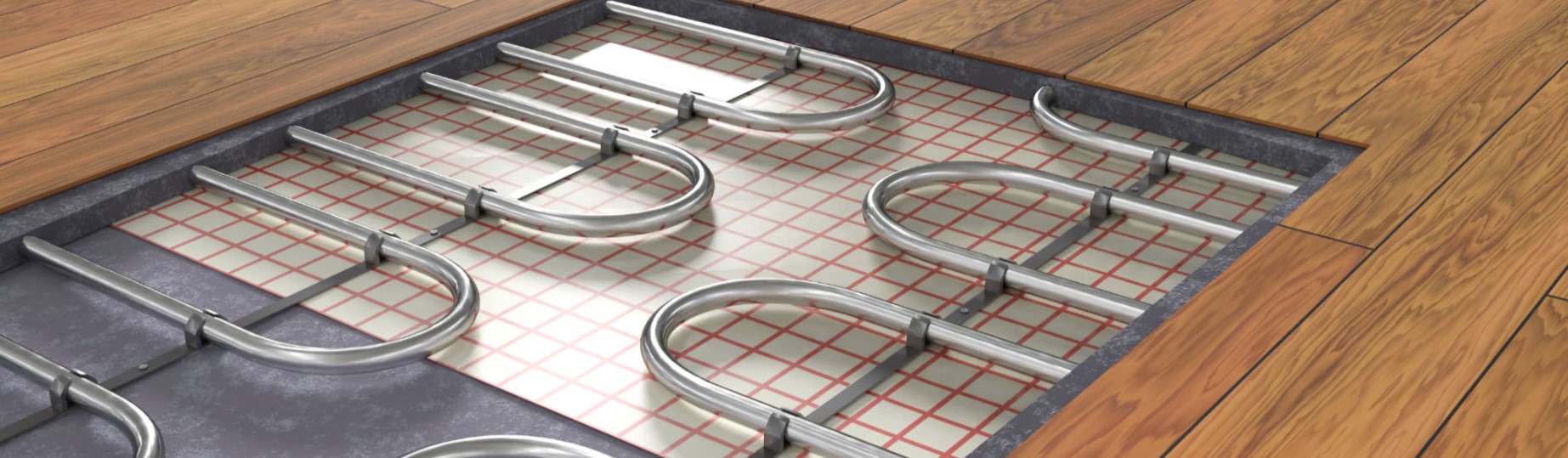

Radiant Subfloor heating

NOTE: Always

make sure that the selected

product is recommended for this type of installation. Some species are not compatible and cannot be installed on this

type of subfloor; Jatoba, Maple, Kempas, Ironwood, Ipé, Asian Mahogany are some

species that are not suitable for Radiant heating. Please ensure that the

species you have chosen is suitable.

- The heating system must be functional and working for at least 7 days prior to the floor installation.

- Stop the heating and let the floor cool down to ambient temperature for 3 or 4 hours before

starting the floor installation.

- Immediately start the radiant

heating system after the installation. The temperature of the finished surface cannot go over 27 °C (80

°F) at all times for the duration of the flooring’s life span.

- Radiant

heating systems usually procure a dry heat which can lower the ambient humidity

level. It could be necessary to use a humidifier to maintain a recommended level

of 40 % to 55 % and prevent

any damage to the floor.

- Flooring

installed on a radiant heating system must be glued at each end, in order to

reduce the shrinkage in length.

Apply a layer of recommended wood glue on the grooved

side before inserting the strip.

- The heating system must be functional and working for at least 7 days prior to the floor installation.

- Stop the heating and let the floor cool down to ambient temperature for 3 or 4 hours before

starting the floor installation.

%20(1000%20×%20700%20px)%20(1000%20×%20650%20px)%20(1000%20×%20670%20px)-700x500w.png)

9822 Comment(s)

I enjoyed reading this. Well-written and informative.

Thanks for sharing this informative post.

The Rice Purity Test originally comes from Rice University, created in 1924 as a playful way for students to share and reflect on their experiences. Over time, it has grown into a global phenomenon, embraced by people of all ages and backgrounds. The test is a self-assessment designed to measure your level of “purity” based on a wide variety of life experiences everything from relationships, partying, and social interactions to personal habits and choices.

If you're looking for a simple, zero-registration alternative to Omegle, check out OmegleChat.tv. It's fast, completely free, and connects you instantly with strangers

Great article! I thoroughly enjoyed reading your article and it provides a fresh perspective.

I particularly liked your point about the importance of individual actions

The author did an exceptional job of presenting the information in a clear and concise manner, making it easy to follow along

This blog post is an absolute gem! I was captivated by the writer's engaging style and the way they effortlessly conveyed their ideas

Wow, what a fantastic article! I thoroughly enjoyed reading it from start to finish.

The author did an exceptional job of presenting the information in a clear and concise manner, making it easy to follow along

Zing Apparel offers you premium leather jackets and bags with finest cuts and vogue collection in fair prices to evoke the feeling of luxury and class.

This blog post is an absolute gem! I was captivated by the writer's engaging style and the way they effortlessly conveyed their ideas

顶尖的北美作业代做 http://www.emwchinese.com/store/info?id=13 机构会有一个专业、经验丰富的团队,他们拥有在相关领域的学位和经验。会保证文章的原创性,防止抄袭,并提供质量保障。

Cheap Handbags Wholesale Are you ok merely repost this in my site? I’ve to grant credit where it really is due. Have a very great day!

Wonderful blog! I found it while browsing on Yahoo News. Do you have any suggestions on how to get listed in Yahoo News? I’ve been trying for a while but I never seem to get there! Many thanks

Good job on this article! I really like how you presented your facts and how you made it interesting and easy to understand. Thank you.

I like what you guys are up too. Such smart work and reporting! Keep up the superb works guys I have incorporated you guys to my blogroll. I think it will improve the value of my website

It’s in point of fact a great and useful piece of information. I am glad that you just shared this useful info with us. Please keep us informed like this. Thank you for sharing.

it is always a good idea to get event planners when you want a good outcome for your planned event`

Thanks for this post, I am a big big fan of this internet site would like to proceed updated.

I had been honored to obtain a call from a friend as he found the important guidelines shared on the site. Browsing your blog post is a real wonderful experience. Thanks again for thinking of readers like me, and I hope for you the best of achievements as being a professional discipline.

Your website is like a digital haven for me. The design is so polished and the content is always enriching. Keep up the amazing work!

I have seen a lot of useful points on your web-site about pc’s. However, I’ve got the view that lap tops are still more or less not powerful more than enough to be a option if you typically do tasks that require a lot of power, including video enhancing. But for website surfing, microsoft word processing, and majority of other prevalent computer functions they are perfectly, provided you do not mind the small screen size. Appreciate sharing your ideas.

Appartamenti in affitto in italia da privati agenzie monolocale bilocale trilocale prezzo regione campania lombardia lazio roma milano napoli padova torino trieste piemonte torino palermo genova bologna bari ferenze catania verona

The first social network dedicated to the death, dying, funerals and memorials. Search for deceased and milions of death records worldwide

Leave a Comment